Do you share our interest in mechanics and gears?

Our gear manufacturing specialists will tell you more about one of the most commonly used types of gears: helical gears.

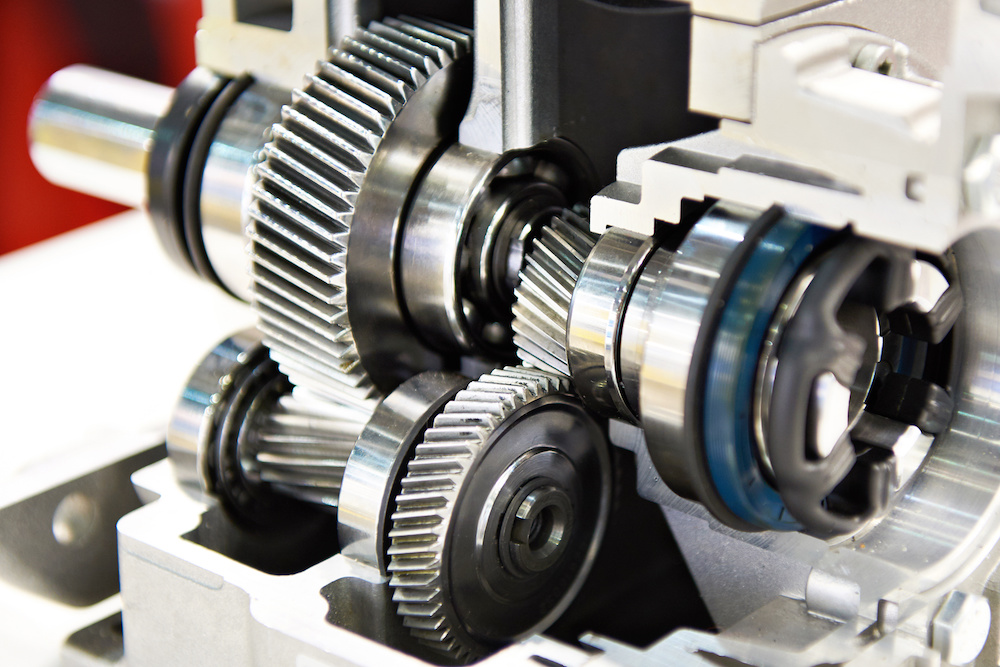

Helical gear characteristics

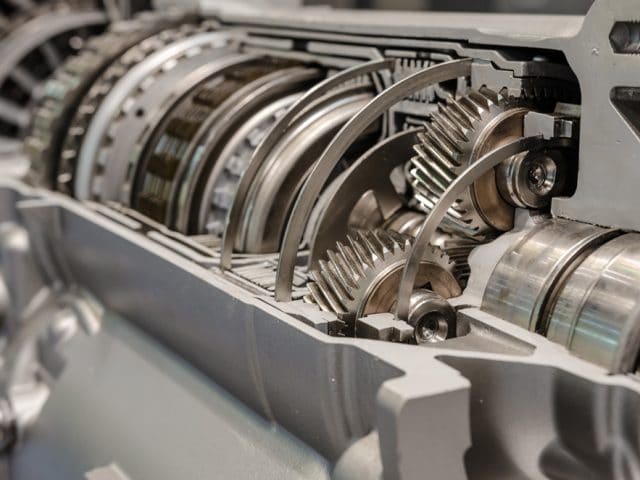

Helical gears are defined by their unique design with angled cuts at the edge of the gear. They reduce friction, heat and noise exceptionally well in comparison to other types of gears. Each gear tooth is designed to interlock with the teeth of the opposing helical gear, which rotates in the opposite direction.

Helical gears work like any other gear that rotates via interlocking teeth, but they are more tempered and progressive than other types. This is largely due to the way their teeth interact with the axis rotation, which can either be parallel or crossed at a 90-degree angle.

Advantages of helical gears

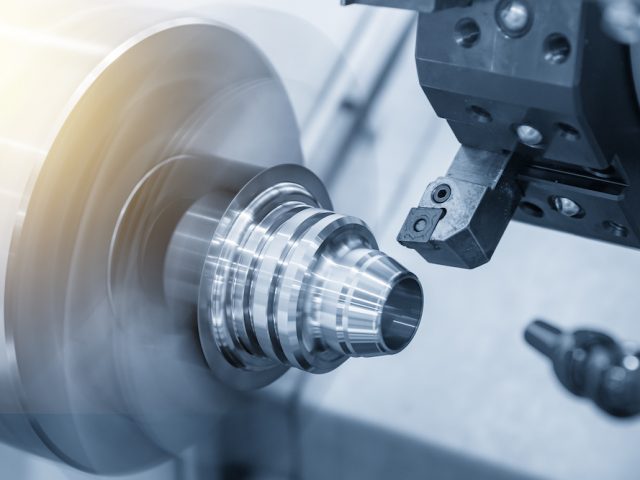

The manufacturing of helical gears gives them unique properties often seen as advantages.

For example, these gears are ideal for high load applications due to the increased number of teeth in contact during motion. They also have many uses since they can transfer motion and power on parallel and right-angled axes.

Helical gears are also known for their durability since they distribute load evenly over the axes, reducing wear over time.

Finally, their inclined teeth come into contact slowly and gradually, which makes them much quieter and promotes steady, hassle-free operation.

Types of helical gears

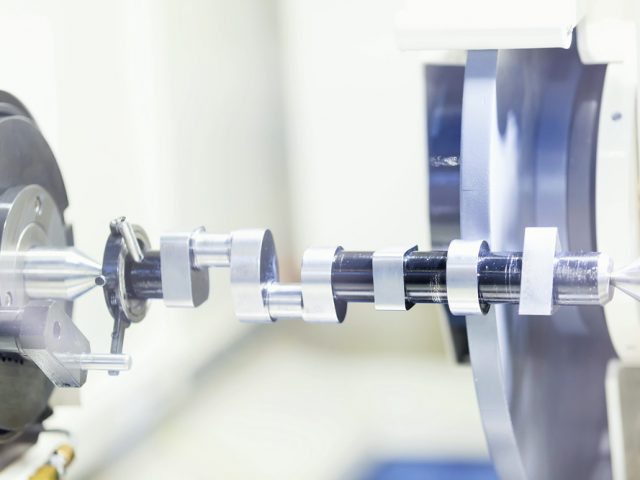

When it comes to gear manufacturing, single and double helical gears can be custom-made. Single helical gears consist of a single row of mitre teeth cut or inserted on the gear body perimeter, while double helical gears consist of two rows of mirrored mitre teeth.

The advantages of double helical gears over single ones are increased resistance and durability and the elimination of axial loading.

Other types of helical gears

Chevron gears are a type of double helical gear where two tracks of teeth touch and form a V rather than being separated by a groove.

Worm drives are used for non-parallel and non-intersecting configurations. These gears have relatively low loading capacities and efficiency rates and are not suitable for high power transmissions.

Common uses of helical gears

Helical gears are often used in transportation and manufacturing. They are commonly found in transmissions due to their smooth operation and low noise level, even at high speeds.

They are also used for applications that are suitable for spur gears but have non-parallel shafts.

Braidwood Industries Ltd.: helical gear specialists in Quebec

Now you know more about helical gears! Hopefully this article satisfied your curiosity about gears.

For any of your needs concerning helical and other gears, visit Braidwood Industries Ltd. Our experienced staff can answer any of your questions and provide personalized service.

Contact us today!