Gears, the unsung heroes of mechanical systems, have played a pivotal role in shaping human civilization. Their origins trace back to ancient civilizations, where they revolutionized agriculture, water management, and timekeeping. Today, gears continue to be indispensable components in a vast array of machines from intricate watches to towering wind turbines.

The earliest evidence of gears dates back to the 5th century BC in China, where they were used in water-raising devices. Around 250 BC, the Antikythera mechanism, an astonishingly sophisticated astronomical calculator, emerged, showcasing the advanced gear technology of the time. By the Middle Ages, gears had become ubiquitous in Europe, powering everything from windmills to flour mills.

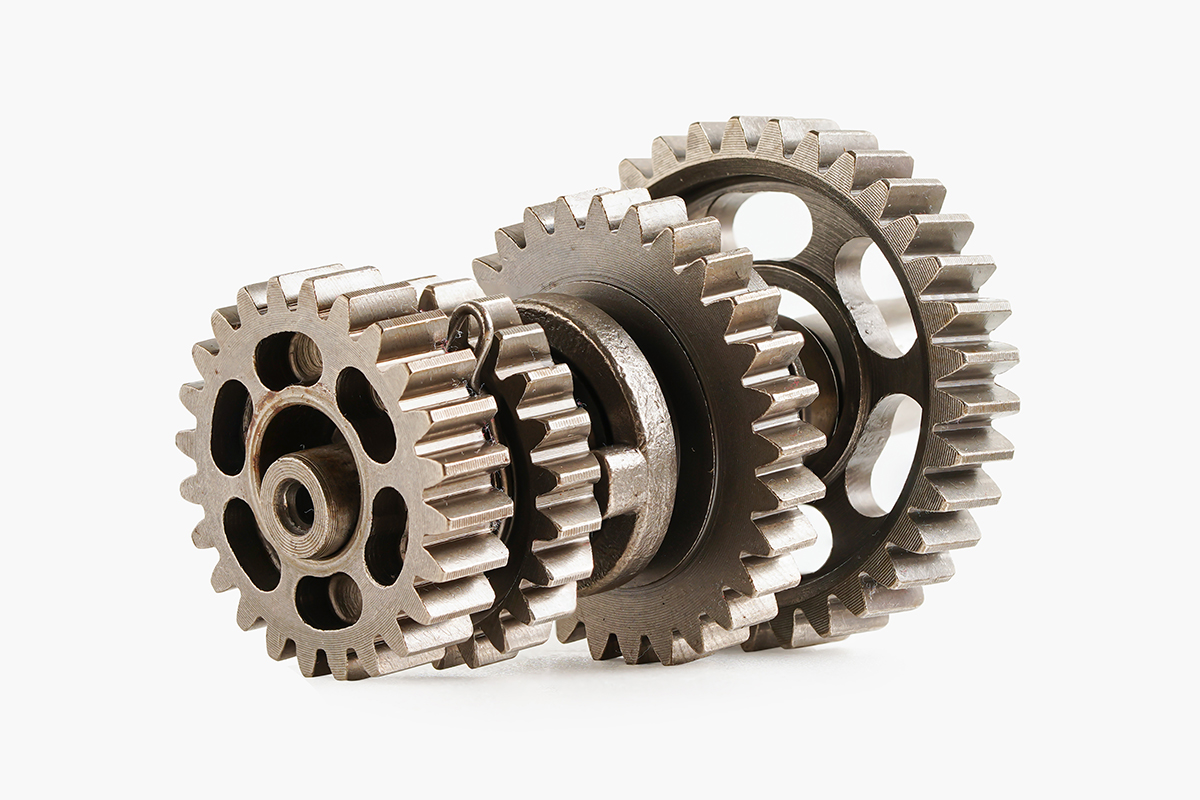

Gears are the workhorses of mechanical systems, providing a versatile means of transmitting torque and power. They allow for the rotation of one shaft to be transferred to another, often with a change in speed or direction. This fundamental principle has enabled a multitude of mechanical innovations throughout history.

Gears are not just about power transfer; they are also precision instruments. Their precise tooth profiles ensure smooth, efficient operation, minimising noise and vibration. This precision is crucial in applications where accuracy and reliability are paramount, such as medical devices and aerospace systems.

In the contemporary landscape, the demand for gears is evolving in tandem with advancements in technology and the quest for efficiency. As industries strive for enhanced performance, reliability, and compact designs, the spotlight on gear innovation has never been more intense.

Gears, the workhorses of mechanical systems, have undergone significant advancements in recent years, driven by the ever-increasing demand for efficient, reliable, and compact power transmission solutions. These advancements encompass a range of innovative approaches, including the development of advanced materials, the adoption of additive manufacturing techniques, the application of topological optimization algorithms, and the integration of smart technologies.

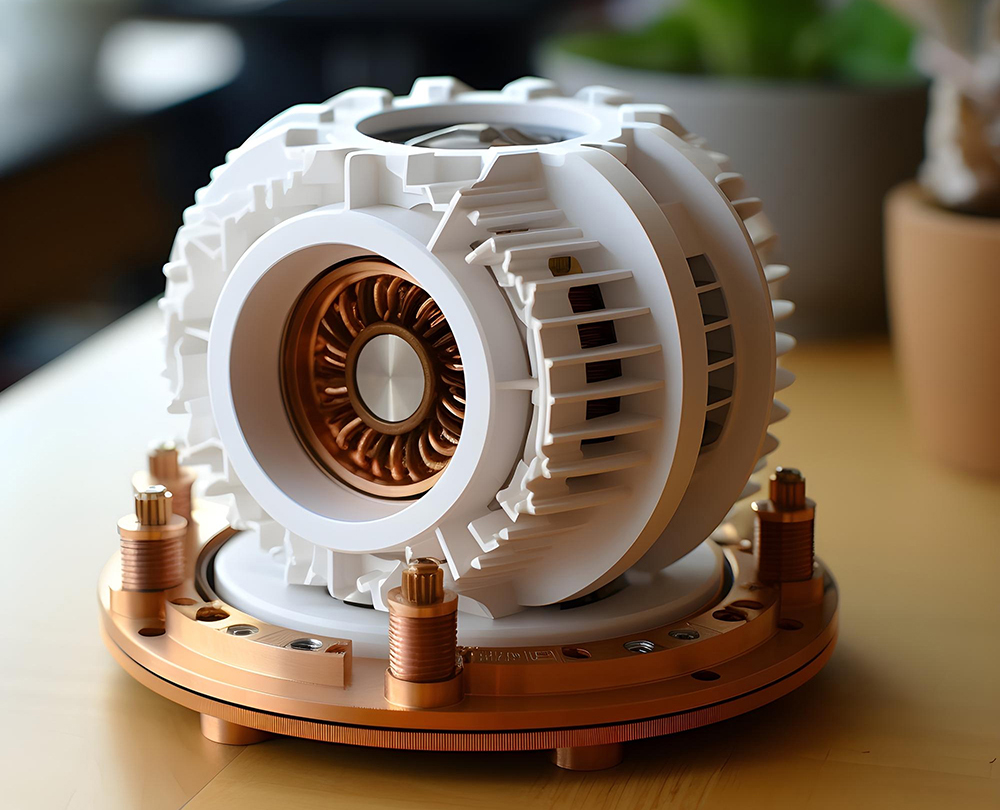

Additive manufacturing, also known as 3D printing, has transformed the gear manufacturing landscape, enabling the production of complex gear geometries and customised designs that were previously impractical or impossible to manufacture using traditional methods.

3D printing offers several advantages over traditional subtractive manufacturing techniques, such as milling and machining. It eliminates the need for tooling and fixtures, reducing lead times and production costs. Additionally, it allows for the creation of complex internal structures and intricate geometries that are not achievable with traditional methods.In gear manufacturing, 3D printing is particularly valuable for producing gears with optimised tooth profiles, tailored to specific load-bearing and efficiency requirements. It also enables the fabrication of custom gears for unique applications or replacement parts for legacy equipment.

In the ever-advancing landscape of technology and machinery, the design of high-speed gears has become a paramount challenge. With the escalating demand for machinery to operate at higher rotational speeds, gear designers are confronted with the intricate task of ensuring noise reduction, vibration control, and optimal efficiency. Noise reduction strategies encompass precision in tooth profiling, employing surface treatments like nitriding, carburizing, and enclosing gears within sound-absorbing materials. Vibration control is achieved through dynamic balancing, damping mechanisms, and the incorporation of stiff gear structures.

Meanwhile, achieving efficiency in high-speed gears involves careful selection of low-friction materials, the optimization of tooth profiles, and the implementation of efficient lubrication systems. Simultaneously, the trend of miniaturised gears is gaining momentum, responding to the need for compact and powerful devices in various industries. The design challenges for miniaturised gears include precision manufacturing, material selection for strength-to-weight ratios, and the development of innovative manufacturing processes such as micro-milling and micro-electro-discharge machining. These miniature marvels find applications in robotics, medical devices, and aerospace, contributing to precise and controlled movements.

Furthermore, the imperative of sustainability has become a focal point in gear design. Designers are adopting eco-friendly materials, energy-efficient manufacturing processes, and end-of-life considerations to reduce the environmental footprint of gears. In conclusion, the realm of gear design is evolving dynamically, driven by the pursuit of high performance, reliability, and environmental responsibility, ushering in a new era of innovation and efficiency.

The evolution of gears reflects their enduring importance from ancient times to the present day. Gears have been essential in agriculture, timekeeping, and modern machinery. Today’s gear design trends like advanced materials, 3D printing, and smart technology, demonstrate a commitment to efficiency, reliability, and sustainability. High-speed gears address challenges like noise reduction and vibration control, while miniaturised gears find applications in robotics and medical devices.

Sustainability is a growing focus, with eco-friendly materials and energy-efficient manufacturing. As gears continue to evolve, they remain the unsung heroes, adapting to new demands and contributing to a more efficient and interconnected world. The story of gears is not just history; it’s an ongoing journey of innovation shaping a better future.